Lift Table Guards – Safety and Lift Table Bellows

Why use a safety lift table guards?

Sure you can have a lift table without a safety guard or bellow, but why risk your employees’ safety with the dangerous pinch-points in the moving scissors?

A safety lift table guards (also known as lift table bellow, accordion skirting, or scissor lift table guard) comply with the OSHA specifications to keep operators safe and prevent injuries as well as hydraulics free from debris. This means less maintenance and more productivity!

How a lift table guard is mounted

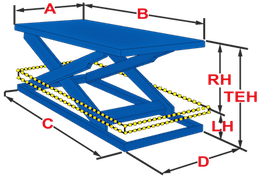

Accordion lift table guards typically mount on the outside of the platform, however, the convolutions/folds would fall either under the lift or outside. When quoting we ask if you are requiring an inside or outside mount, however, we are really asking if you want the folds to fall under that platform of the lift table or outside the platform. Internal mounting or beveled toe mounting is typically for lifts operated in a pit or limited space around lift table. For inside mount the base of the lift table must be smaller than platform size allowing clearance for table to freely raise and collapse without pinching or hitting skirting.

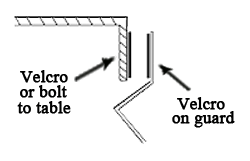

In addition to standard flat bar mounting, our lift table guards can be used with Velcro®. The Velcro® Mounting loop is sewn to the lift table guard itself and a pressure-sensitive hook is applied to the table lift. Velcro® mounted lift table guards can easily be removed for table lift cleaning and maintenance.

Outside vs. inside mounting depends on where the convolutions fall; outside of the lift table or inside/flush with the lift table.

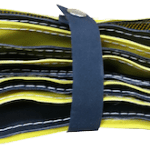

- High Quality Material

- Venting Panel

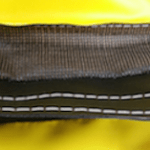

- A Closer Look

Built to Last

All OTCO, Inc. scissor lift table guards are sewn with the highest-quality materials. This inside view of the standard lift table guard shows how the OTCO, Inc. web “tie-tapes” are sewn to the inside of each convolution. These web tapes provide extra stability and uniform expansion and contraction of the bellows during operation of the lift table.

All 4-sided OTCO, Inc. lift table guards have a durable, vinyl-coated, mesh venting panel sewn into the upper convolution for the release of air, or the drawing in of air, during normal lift table operation.

Customized Design

All our lift table guards are hand-crafted by leading professionals. They are designed to fit your lift table, per your supplied dimensions – so you’ll know they’ll fit!

Convolution Size

Convolution is the width of each fold. Standard convolution size is three inches, but can go as small as one inch. Typically, smaller convolutions are used when they need to not interfere with the table lift mechanisms. Other times, they may be adjusted so the table lift skirting doesn’t stick out as far from the table.

According Lift Guards or Skirting

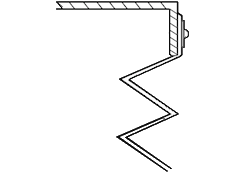

Our accordion lift table guards or skirting are made with spring-steel rods, supporting each convolution. The rods are totally enclosed with no metal edges exposed. Rods are included as a standard feature with each OTCO Lift Table Guards and can be easily installed in the field or at our factory.

- Internal webbing to prevent over extension

- Lift Table Specs

- Steel wires are placed in the folds to add rigidity to the bellows

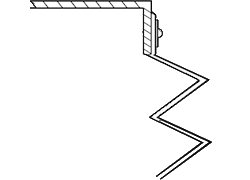

OCTO, Inc. Roller Curtains for Lift Tables

Roller Curtains for lift tables provide a straightforward alternative to the Accordion Lift Table Guards. This is important when space is limited and the complete seal of a “bellows cover” is not required.

Roller brackets are provided with each lift table guard for attachment to the bottom of the unit. Roller Guards will be made from Tip to Tip from the width dimension given to us.

Additional Options

Material Type:

18 oz Vinyl

22 oz Vinyl

Fire Resistant – Norfab material

Material Color:

Black & Yellow

Yellow

Black

Blue

Stiffening Wires:

Steel wires are placed in the folds to add rigidity to the bellows.

Velcro Closure:

For easier installment lift table skirts can have velcro corner closures added.

Mounting Options

Outside vs. Inside mounting depends on where the convolutions fall, outside of the lift table or inside/flush with the lift table.

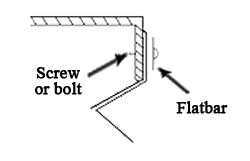

Flat Bar vs. Velcro Mounting

Each skirt has a 3″ lip that can be bolted or Velcro® attached to the lift table. Flat bar is the longest lasting however some prefer Velcro® for maintenance reasons.